But how did our UK plant achieve such an impressive feat?

The secret lies in processing a diverse range of materials like solid wood, plywood, MDF, and chipboard. Each of these materials, chosen for its specific quality and finish, gets transformed with a veneer wrap, paper decors, PVC foils, or a lacquer finish. This dedication to variety and quality has earned us the trust of some of the UK’s leading furniture and kitchen manufacturers. The cherry on top? Our ISO 9001 accreditation stands as a testament to our unwavering commitment to quality.

Managed, renewable forestry

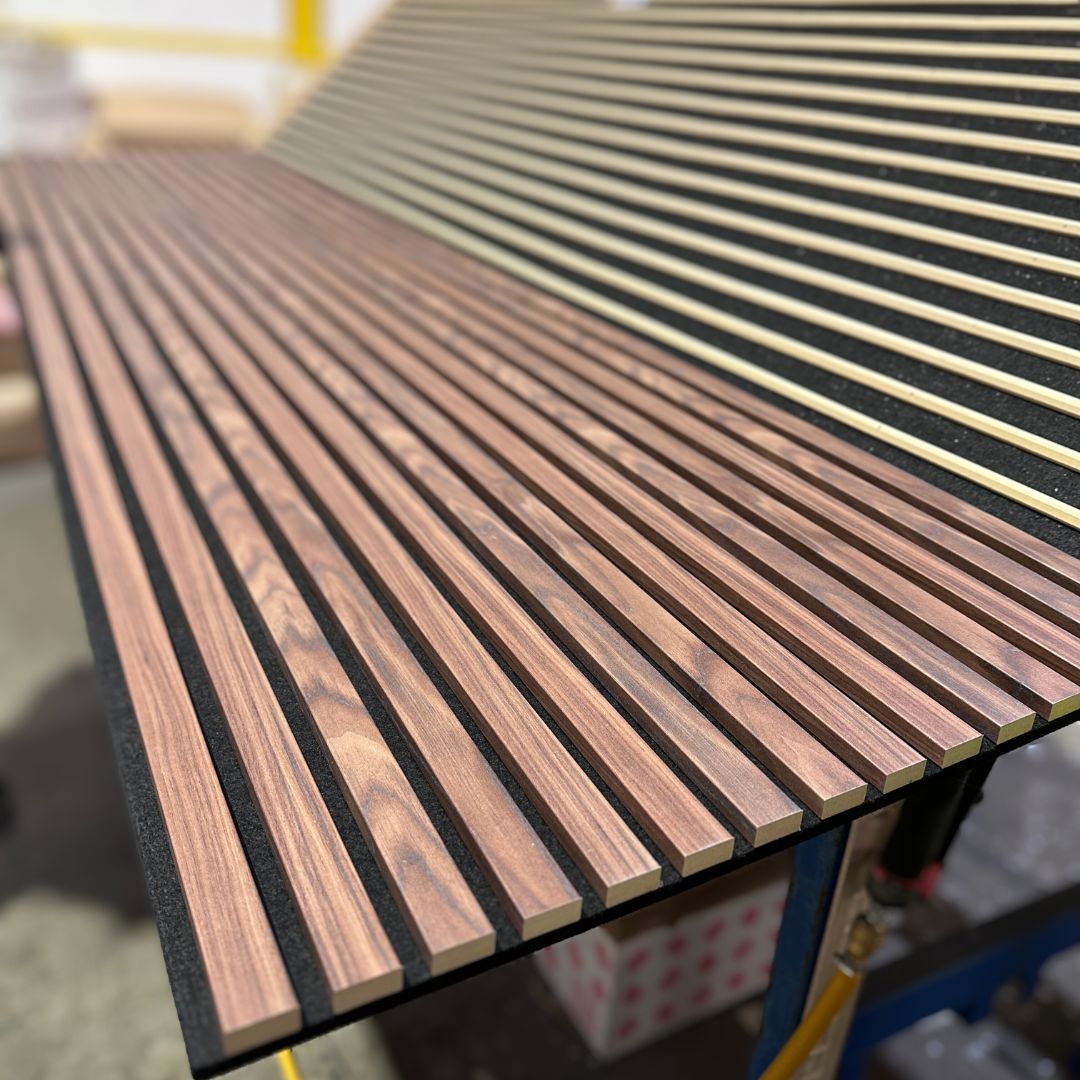

Our slat wall panels are crafted using two primary materials: MDF (medium-density fibreboard) and paper foil, both made from managed, renewable forestry.

. This ensures sustainable practices and minimises environmental impact. The MDF, sourced from southern Ireland, is made by breaking down tree trunks into small wood fibres, which are then bound with resin, compressed, and heated into solid boards. These 12mm thick boards are efficiently cut to match product specifications in our factory. Following this, they undergo assembly where paper foils are bonded using PUR glue, and an automated buzzsaw then cuts them to the final size, ensuring precision and quality in every panel.

Producing our slat wall panels

Veneer vs. Paper

The design and decor world is no stranger to debates and dilemmas. And at the heart of our slat wall development process lay a significant question: Veneer or Paper? With an extensive stock of both materials, the choice wasn’t straightforward.

Initial instincts hinted towards veneer. After all, in 2022 alone, we had manufactured over 400,000 metres of veneered products. However, when we brought our samples – crafted in both finishes – to our focus groups, the tables turned dramatically. While most had a preconceived preference for veneer, the actual touch, feel, and look of the paper decor won hearts.

Every groove tells a story of expert craftsmanship

But why did paper decor edge out its seemingly fancier counterpart? The reasons are multifold. Veneer, despite its upscale image, comes with the downsides of a sharp, rough edge. On the other hand, paper decors feel soft and are much more user-friendly.

Maintenance? Veneer demands regular oiling to keep issues like shrinkage, cracking, and discolouration at bay, while paper decors reign with their hassle-free care. And when you weigh in the environmental benefits, paper decor is a no-brainer!

They’re softer to the touch with smoother corners

No upkeep required – real wood requires periodic varnishing

Easier to clean with just occasional dusting

No bare MDF as the foil covers all three visible sides, whereas real wood veneers typically only cover the front

Realistic yet consistent wood grain effect

Our commitment goes beyond aesthetics and functionality. We proudly sport a green heart, ensuring that the wood products we use comes from responsibly managed sources.

While many slat walls in the UK have journeyed from the far east, our products stay close to home. From using MDF sourced from Irish and Scottish mills to choosing paper decors manufactured in Germany, our focus is on reducing the carbon footprint. Our unique touch? The felt backing on our slat wall panels, developed exclusively for us by a Yorkshire mill.

Our unique touch? The felt backing on our slat wall panels, developed exclusively for us by a Yorkshire mill.

Taking our environmental commitment up a notch, 2023 saw us harnessing solar power with a robust installation that produces electricity equivalent to powering over 400 homes. Couple that with our £600,000 biomass boiler, and it’s evident that we’re dedicated to green energy, aiming to reduce our net grid electricity consumption massively.

Our solar-powered production site in Peterlee, Durham

When clients compare our slat wall panels to competitors, the remarkable price difference often leaves people pleasantly surprised. But rather than a compromise on quality, it’s our state-of-the-art manufacturing processes that make this possible.

From the very beginning, investments in robotic cells, lean manufacturing techniques, and automated in-line wrapping lines have been our pillars. This not only speeds up the production process, but also ensures each product meets our stringent quality checks.

Additionally, our bulk purchasing strategy, straight from mills or factories, allows us to get premium materials at unparalleled rates. And here’s the clincher: our slat wall panels don’t bear the burden of our factory overheads or staffing costs, which are offset by our furniture and kitchen ventures. This unique business model enables us to bring to you an unbeatable blend of affordability and quality.

© Copyright 2025 Slat Decor Privacy Policy Terms of Use Consumer Terms & Conditions Returns Policy QA & Complaints Policy Website by Pivotal Marketing